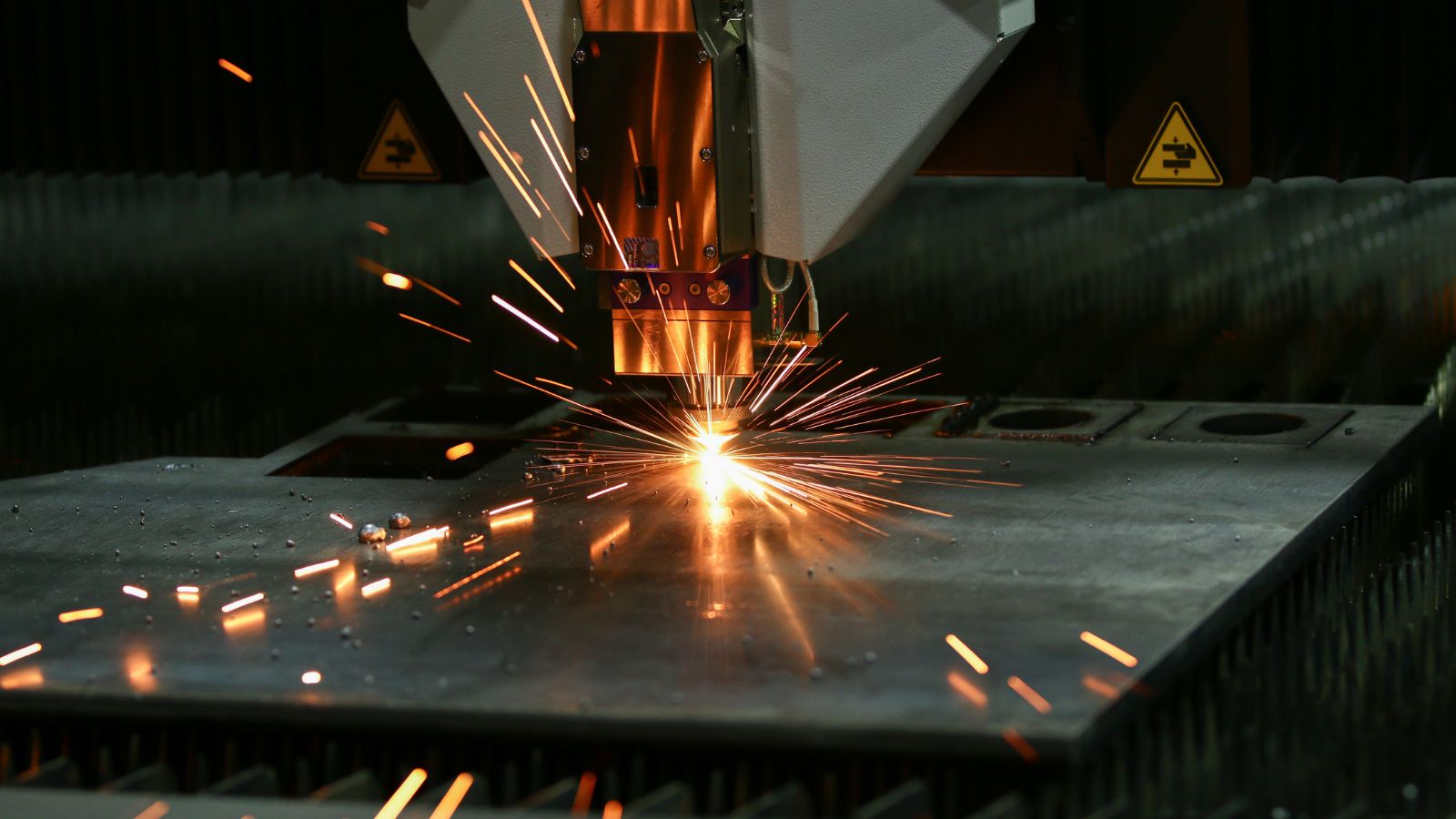

Choosing the right laser for material processing can make a significant difference in the quality and efficiency of your production. When working with materials like metal and acrylic, the question often arises: CO2 laser or fiber laser – which one is better for your needs? In this article, we will take a closer look at both types of lasers and explain which is the best choice for different applications.

What is a CO2 Laser?

A CO2 laser is a gas laser that uses carbon dioxide as the active medium. With a wavelength of 10.6 micrometers, it is particularly well-suited for cutting various materials, including metal and acrylic. These lasers offer high precision and excellent cutting quality, especially for thinner materials. They are incredibly versatile and can cut not only metal but also wood, plastic, and many other materials. Wattsan offers CO2 laser machines known for their performance and high cutting quality, making them suitable for many manufacturing applications.

Advantages:

- Provides precise cuts, especially for thin materials.

- Excellent for cutting acrylic are ideal for creative projects and detailed work.

- Highly versatile are capable of cutting a wide range of materials.

What is a Fiber Laser?

Fiber lasers use a fiber-optic medium that is pumped with a solid-state laser. With a wavelength of approximately 1 micrometer, they are particularly effective for processing metals. Fiber lasers are known for their high efficiency and their ability to cut even thicker metals quickly and precisely. If you are looking for a powerful and fast solution, Wattsan offers various fiber laser models that provide exactly that: they combine high precision with fast processing, making them perfect for industrial applications requiring high speed and accuracy.

Advantages:

- Highly energy-efficient, saving operating costs in the long run.

- Especially suitable for cutting thicker metal plates are faster and more efficient.

- High power and speed in metal processing, accelerating production.

CO2 vs. Fiber Laser

When comparing CO2 and fiber lasers, there are several key differences in terms of performance, speed, and applications. Here are the main aspects to consider:

- Performance and Speed: If you work with thicker metals, a fiber laser is probably the better choice. It not only offers more power but also cuts faster. CO2 lasers are slower on thicker materials, but they deliver excellent results on thin materials and acrylic. So, if you frequently work with acrylic or thin sheet metal, a CO2 laser is ideal. Wattsan offers both CO2 and fiber lasers, each excelling in its own way.

- Cut Quality: Both laser types provide excellent cut quality, but on different materials. The CO2 laser produces very clean cut edges on thin materials, while the fiber laser excels in cutting thick metal plates. If you prioritize precision and clean cutting edges, whether in acrylic or metal, Wattsan ensures you get a machine that meets your needs.

- Cost: A significant advantage of fiber lasers is their energy efficiency and lower maintenance requirements, leading to reduced operating costs over time. Although the initial cost of a fiber laser is often higher than that of a CO2 laser, you save on operational expenses in the long run.

How to Choose the Greatest Laser for Your Production?

The choice between a CO2 and a fiber laser depends on the materials you primarily work with. If you frequently process acrylic or thin metal, a CO2 laser is an excellent option. For thicker materials and faster processing, a fiber laser is the better choice. Wattsan offers both CO2 and fiber laser machines, allowing you to select the best option based on your specific needs.

It’s worth comparing different models and finding the best solution for your production. You can get detailed consultations and explore laser machines that perfectly match your requirements on the Wattsan website: https://wattsan.com/

Conclusion

Both CO2 and fiber lasers offer unique advantages and are well-suited for different applications. CO2 lasers excel at processing thin materials and acrylic, while fiber lasers stand out for their high efficiency and performance in cutting thicker metals and speeding up production processes. By taking the time to select the right laser for your needs, you can not only improve the quality of your work but also reduce operating costs in the long run. Discover the perfect laser solution for your business today – at Wattsan, you will find a wide range of machines tailored to your requirements.