When choosing equipment made of copper and other metals with high temperatures, you would want to find durable ones. Precision die casting is an effective manufacturing process that produces strong and denser metals; these metals are long-lasting and are suitable for long-term projects.

Thus when buying your metals, you will ask about the casting methods https://www.ekoindustries.com/precision-die-casting/cold-chamber-die-casting sells the best precision die-casting metals. Die casting uses molten metal to create a mold in the machine chamber, creating dense metals. Here are the advantages of die casting and why you should choose equipment created through this process.

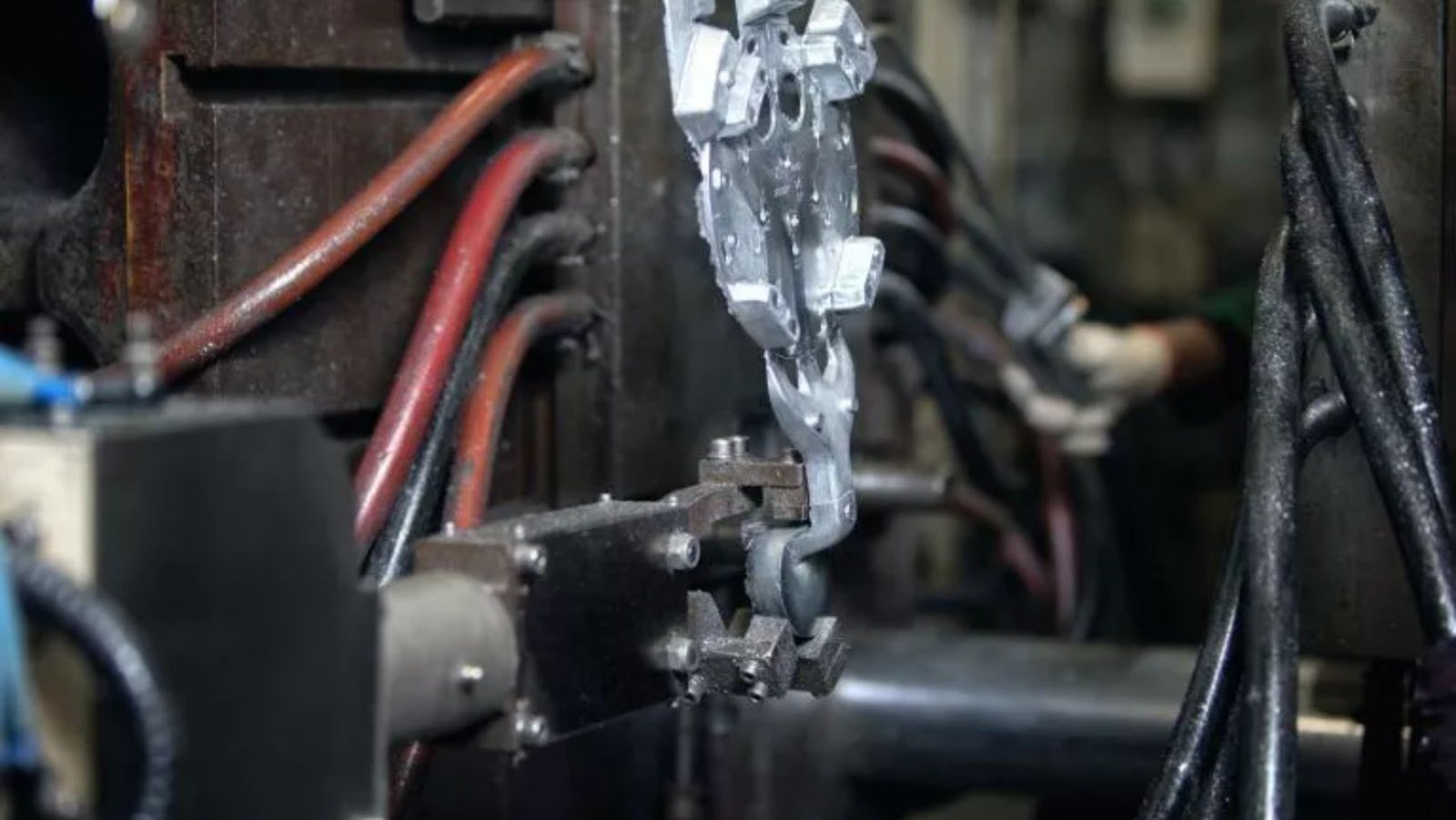

What Is Die Casting

Die casting is a volume production process that uses high heat to melt metals like copper and aluminum. The manufacturer will pour the molten metal into the chamber, forming a denser metal.

The die-cast process leads to add-ons that eliminate the assembly and machining, thus reducing the production costs. The process does not need any machines, but it produces complex-shaped equipment making the casting process economical and efficient.

It Produces Long-Lasting and Robust Components

Die-cast in the cold chamber can create strong and long-lasting parts; the equipment made from dense metal will last more than the ones from regular metals. Thus, you can choose the robust components with improved appeal, surround and functionality. For instance, the metals made of regular metal will disintegrate faster than those from the die casting.

It Is a Cost-Effective Process

The manufacturer can cut costs with the die casting process as they only need high heat, which can melt the metals, and a casting chamber to create dense metals. Mostly the manufacturer will incur the costs of melting the metals while creating a range of components.

The other manufacturing processes might not yield similar results. Manufacturers who use green energy might lower the production costs further as the die casting does not need the industrial shaping and smoothing of the equipment.

The Products Are Easy To Assemble

You can create studs; it is easy to carve holes in the chamber and add external threads. You can customize the chamber shape to create ideal shapes.

Thus it is easy to create any equipment with the molding and meet the aesthetic needs. The finished products are better as the chamber smoothens the rough edges leading to a high-level finish. You can plate the products with little menial effort.

It Has an Accurate Dimension

You can achieve accurate dimensions with the casting chamber, which is easy to customize. You will take the proper measurements of the machine moving parts and apply the same measurements to the molding chamber to achieve the right dimensions. The equipment is dimensionally stable, heat resistant, and might have a high tolerance level.

Final Thoughts

Choosing metallic equipment is difficult, especially if you don’t know what to look for in the equipment. However, you should choose denser metallic equipment with smooth surfaces and increased durability.

Die casting produces durable materials, denser than those made through the normal industrial process. You should ask the retailers or manufacturers about the metal creating process and choose the ones made through the die casting process.